The question of UV piping vs. corrugated metal piping dates back to the beginning of pipe repair history. Pipe repair can be challenging, especially when extensive damage is involved. Hence, many property owners and managers need help to decide on a suitable fix for their pipe systems.

UV piping in cured-in-place pipe repair (CIPP) is the conventional relative of trench pipe repair. Trench pipe repair is the traditional technique for repairing damaged pipelines. It involves the standard dig-and-trench, meaning specialists must unearth the damaged line to replace it with a new pipe.

Read on as learn more about UV piping and corrugated metal piping, their differences, and their applicability in different pipe repair scenarios.

What is UV Piping?

UV piping, or CIPP lining, is a trenchless way to repair damaged underground pipes. Traditionally, pipeline specialists had to break up the landscape, dig out the line, and entirely replace it. This method caused extensive damage to the surrounding area and resulted in high repair and replacement costs.

Today, however, cured-in-place pipe repair (CIPP) is famous around the globe. CIPP lining affords experts and property owners a non-destructive way to repair faulty pipe systems. With UV piping, specialists can cure a previously installed epoxy liner to form a protective layer within the existing pipe.

UV lining is faster and more economical, making it ideal for residential, commercial, and industrial properties.

How Does UV Piping Work?

Here’s a detailed breakdown of the process:

- Cleaning: Before performing CIPP, experts ensure the site is clear by cleaning the affected line. This helps them pinpoint the fault, assess its extent, and determine a suitable route to tackle it. They often use high-pressure water to wash down the line, pushing debris and clogs further down.

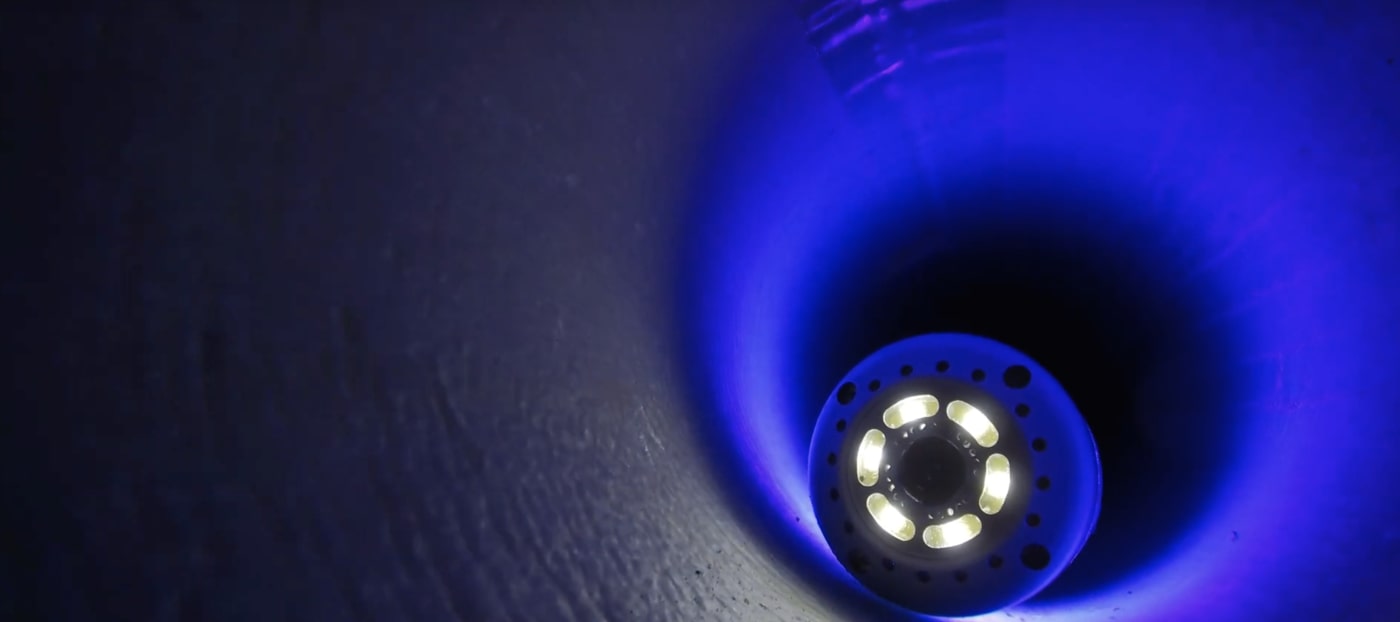

- Inspection: Now that the site is clear, experts can examine the pipe with a video camera. The video inspection helps them to determine a good access route.

- Access point: With knowledge from the assessment, experts drill a small hole into the pipe, called an access point. The access point’s location is strategically determined to ensure the operation’s success.

- Insertion: Through the access point, they pull or push a flexible resin liner into the existing pipe. Then, they use air or water pressure to expand the line, coating it against the old pipe’s inner walls.

- Curing: Now that the resin has set, experts use heat or ultraviolet light to cure the resin, hardening it and creating a durable pipe with the old line.

- Final inspection: When the resin has been fully set, experts conduct a final inspection to verify the integrity of the operation. With a video camera, they peer into the line, locate the operation site, and test for cracks and leaks with high pressure. They seal the access point and conclude the procedure if the operation is successful.

What is Corrugated Metal Piping?

Corrugated metal piping is a type of pipe that typically consists of steel and aluminum. Corrugated pipes serve different purposes, including storm drainages, sewage, and culverts. Unfortunately, this form of pipe repair quickly falls out of favor with property owners due to its expensive nature and invasive procedure.

To repair metal corrugated pipe systems, experts must dig them out to replace them entirely, which is disruptive and unsustainable in the long run.

Why UV Lining is Better than Metal Corrugation

Here are some of the reasons property owners prefer CIPP lining over metal corrugation:

It is Fast

CIPP lining excludes all the traditional trenching, meaning experts can complete the process in a matter of hours. The duration significantly benefits property owners because it helps reduce downtime and disruption.

It is Economical

In trench repair scenarios, experts dig out and replace the entire line. As steel is far more expensive than epoxy, UV lining can help save costs for property owners.

Also, trenching leaves an aftermath of damage that requires a small fortune to remediate. In contrast, CIPP uses more economical materials like epoxy. While it’s economical, epoxy is also durable and hardy, making it a long-lasting repair solution.

It is Versatile

UV lining is a versatile pipe repair option because experts can apply the procedure to different pipe scenarios. CIPP lining applies to pipes with varying sizes of diameter and materials, such as clay, steel, plastic, concrete, and PVC.

It is Eco-Friendly

Overall, UV lining is an effective way to maintain your property’s pipe systems without trenching. In addition, experts can safely perform the procedure several times, making it a sustainable and economical alternative to metal corrugation.

If your property is experiencing pipe issues, then we can help. Advanced Pipe Repair’s expert team is equipped with tools and expertise to remediate your pipe systems. In addition, we always conduct a video inspection to assess the damage and determine a suitable fix. Contact us today!